Memory Mattress Sponge Horizontal Continuous Foam Making Machine for Sofa and Shoes

Our range of eps board production line is a new type of packing material also named as pearl cotton.

epe foam sheet/film production line is an ideal substitute of traditional packing material for many advantages including dampproof, shockproof, sound insulation, heat preservation and high plasticity.

As a new type packing material it is widely used in the packing of electronic product, commodity, glass, ceramic, household apparatus, spraying, furniture, hardware product and toy ect .

EPE foam sheet is widely used in the packing of food, fruit, electronic product, daily necessities, hardware product, toy etc.

Main technical parameters of eps board production line

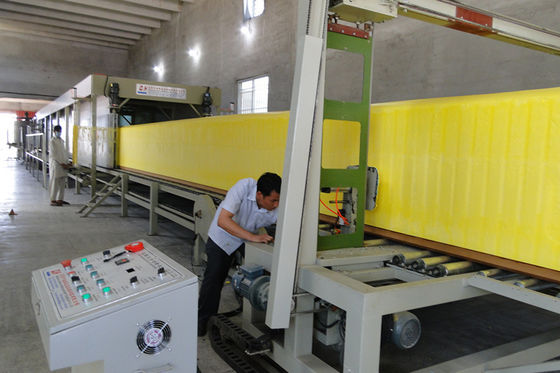

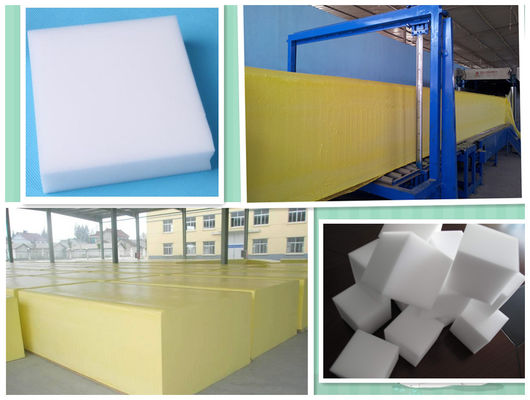

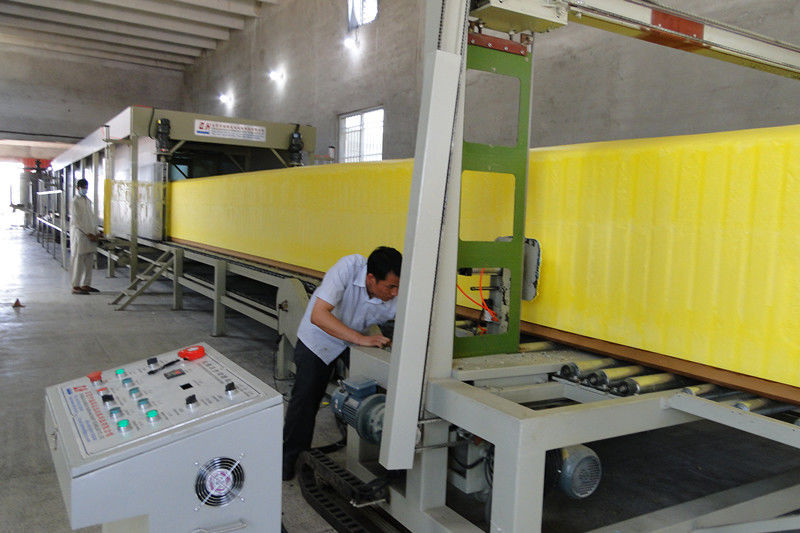

The QHF-2017 Horizontal Continuously foam production line is an automatic continous foaming machine for producing flexible polyurethane foam used in furniture,shoe material,packing,electron,garment and transportation industrial.it's the ideal production equipment for large-scale foaming.

We use the siemens invertor/motor and U.S. viking pump and some good spare parts that good for make the flexible foam. The density we can make is from D8-D100 and we can add abt 50% of the lime powder during density above D23.

Main specification

| Oven Length |

18m |

| Foam Height |

1.0-1.25m |

| Foam Width |

1.0-2.25m |

| foam desity |

8-200kg/m³ |

| total power |

130KW |

| inner coveyer length |

18m |

| side board adjustable width |

0.98-2.3m |

| conveyer belt speed |

0-8m/min |

| fall plate |

seven section adjustable |

| total output |

100-300kg/min |

| machine dimension |

L35× W4.2 ×H3.2m |

Main technique specification:

| Dimension |

Total length 35m×Total width 4m×Total Height 3m |

| Foaming material Group |

13 groups, man-machine interface, both manual and automatically computer control |

| Foaming width |

980mm~2250mm |

| Foaming height |

Max 1200mm |

| Foaming density |

8Kg/m³~100kg/m³ |

| Foaming speed |

2000r/min~7000r/min |

| Max total output |

300kg/min |

| Material spraying way |

① The way of down sprayer head (upper, down, front, back can be adjusted) ② the way of trough overflow pipe. |

| Controlling way of foaming |

①PLC controlling, can continuously foaming two different formulas in one time

②All inverter controlling foaming and work in phase with the production line

③Oven declining board height and width can be adjusted by control box.

④Oven side links width can be adjusted by control box

|

| Mixing –head motor |

|

|

Total power

|

About 90kw |

How is the packing of the machine?

The entire machine will be nude packing. Some of the parts will be pack in wooden case. Others will be simple pack with paper or foam sheet with plastic film.

How many container will be needed for the whole set of machine?

For the standard 13 groups of Automatic continous foam machine Total three containers is enough 2*40HQ+1*20GP. In order to save the place and the cost of delivery we will also put some parts that inside the raw material tank.

We will try the best way to pack all the machine well and also save the freight cost.

Our Services

1.We will help to design the layout of the machine that put in your factory.

2.We will send 2-4 experience engineers to install and testing the machines.

3.We will teach your engineer how to operate the machine and how to maintain the machines.

4.We will give you the machine operation manual and the best formulation for target products that you are going to make.

5.We will help to buy the best raw material for making the foam if you needed.

FAQ:

Q: How many days for the install and testing of the machine?

A: After all the machine in your factory we will send 1-2 engineer help to install the machine you must send someone to help about 30 days installation will finished. After that one electrician and one foaming engineer will come to connecting the cable and run the machine in 15days. Total 45days the machine can be running.

Q: For the cost of the engineer how much I need to pay?

A: You need to pay USD40 one day for one engineer and also need to pay for the visa fee turn-round ticket fee and food hotel.

Q:What kind of raw material tools we need to prepare for the testing?

A: We will send you a list for the tools that you need to prepare for testing and also can help to buy if you required.

Q: After the machine testing if we need some engineer to stay in our factory can you help to find?

A: Sure we can help to hire one experience engineer to work in your factory but you need to discuss the salary and all details with him.

Q:During the foaming if we have some problems abt the foam and the machine how can we do ?

A: You can just call our after sale manager explain for the situation or send some picture we will help to handle within 24hours.

The main part of the machine

INSTRUCTION OF CONTINUOUS FAOMING MACHINE LINE.pdf

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!